HRT Technologies Discription

Release time:

2025-04-27

The latest technology for desulfurization and olefin reduction in catalytic cracked gasoline, awarded the Second Prize of the National Technology Invention Award, and recommended as a promoted technology by the Ministry of Industry and Information Technology.

1. Deep Desulfurization and Selective Olefin Reduction Technology for Catalytic Cracked Gasoline (EHDSO)

Advantages and Features:

The latest technology for desulfurization and olefin reduction in catalytic cracked gasoline, awarded the Second Prize of the National Technology Invention Award, and recommended as a promoted technology by the Ministry of Industry and Information Technology.

Catalytic cracked gasoline is characterized by high sulfur content and high olefin content. Conventional deep hydrodesulfurization under hydrogenation conditions can cause non-selective olefin saturation, resulting in a significant loss of octane number.

This technology leverages the hydrocarbon composition and sulfur form distribution patterns in catalytic cracked gasoline. By coupling extractive desulfurization and hydrodesulfurization, it achieves deep desulfurization while selectively protecting normal olefins from hydrogenation. At the same time, it selectively controls the hydrogenation of cyclic olefins and small-molecule isomeric olefins, thereby reducing olefins while preserving the octane number.

| Technology | S-zorb | Prime-G+ | EHDSO |

| Sulfur content of raw material, ppm | <300 | ~1500 | ~1500 |

| Proportion of olefin facing hydrogen% | 100 | 55 | 15 |

| Total Fraction RON Loss | 0.6-1.5 | 2.0~3.0 | 0.3~1.5 |

| Energy consumption, kg standard oil/t | 8 | 20 | 30 |

| Hydrogen consumption, kg/t | 3 | 3 | 1.5 |

| Loss due to hydrogenation,% | 1.0-1.5 | 0.4~0.8 | 0.2~0.4 |

| Whether it is difficult to treat tail gas | There is | no | no |

| solid spent catalyst | There is | There is | There is (small scale and small quantity) |

| Alkene-lowering measures | passive hydrogenation | passive hydrogenation | active selective hydrogenation |

| Investment (1 million tons/year) billion yuan | 2.5 | 1.5 | 1.8 |

Highly compatible with existing hydrodesulfurization technologies, whether for new installations or capacity expansions. This technology offers significant competitive advantages in terms of capital investment, operating costs, feedstock adaptability, and RON (Research Octane Number) loss.

Strong adaptability to feedstocks: The higher the sulfur and olefin content, the more pronounced the technical and economic benefits.

Achieves a total sulfur content of less than 10 ppm for the full boiling range, with olefin reduction of 8–10% and RON loss limited to 1 unit.

Reduces hydrogen consumption and processing losses by 50% to 67%.

The first technology is the EHDSO (Deep Desulfurization and Selective Olefin Reduction Technology for Catalytic Cracked Gasoline), which represents the latest advancements in gasoline desulfurization and olefin reduction. This technology has been awarded the Second Prize of the National Technology Invention Award and is officially recommended for promotion by the Ministry of Industry and Information Technology (MIIT).

Catalytic cracked gasoline is characterized by high sulfur and olefin content. Using conventional hydrogenation methods for deep desulfurization leads to non-selective olefin saturation, which results in a significant octane number loss. Our technology leverages the distinct characteristics and distribution patterns of hydrocarbon compositions and sulfur forms in catalytic cracked gasoline. Through a combination of extractive desulfurization and hydrodesulfurization, it achieves deep desulfurization while selectively protecting normal olefins from hydrogenation. It further controls the hydrogenation of cyclic olefins and small-molecule isomeric olefins, enabling selective olefin reduction while preserving the octane number.

The table below compares the major desulfurization and refining technologies for catalytic cracked gasoline in China.

- Sinopec's S-Zorb adsorption hydrogenation desulfurization technology.

- Axens' Prime-G+, a leading selective hydrogenation desulfurization technology.

- Hebei Jingzhi's EHDSO extractive hydrogenation combined desulfurization technology.

Octane number loss is the most critical factor for comparison among these three technologies.

- While S-Zorb has relatively low octane number loss, it has significant limitations: its adsorbent restricts the sulfur content of the feedstock, and high olefin content poses challenges.

- Prime-G+ has the highest octane number loss among the three technologies.

- Our EHDSO technology, combining extraction and hydrogenation, minimizes hydrogenation ratios, reduces olefin loss, and achieves lower octane number loss. Hydrogen consumption and cracking loss during hydrogenation are also minimized.

Additionally, S-Zorb generates SO₂-containing tail gas, requiring additional costly treatment.

From an investment perspective, S-Zorb has the highest cost, while Prime-G+ has the lowest investment requirement. However, Prime-G+ suffers from octane number losses of 2–3 units, compared to our EHDSO technology's loss of only 0.3–1.5 units.

In summary, whether for new installations or capacity expansions, Hebei Jingzhi’s EHDSO technology is the best choice. It offers clear advantages in terms of capital investment, operating costs, and octane number retention. Moreover, its strong adaptability to feedstocks, low hydrogen consumption, and increasing economic benefits with higher sulfur and olefin contents further enhance its competitiveness.

To date, this technology has been successfully implemented in 18 industrial projects.

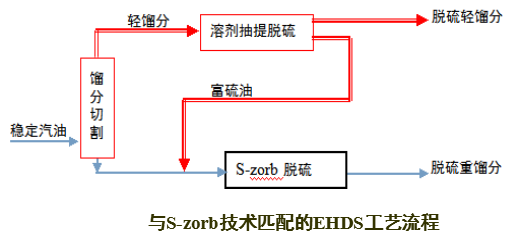

2. Deep Desulfurization and Selective Olefin Reduction Technology for Catalytic Cracked Gasoline – Coupled with S-Zorb

Advantages and Characteristics:

- Simpler and More Cost-Effective Capacity Expansion: Compared to capacity expansion of the S-Zorb process alone, the coupling process is simpler and easier to implement, resulting in lower investment costs.

- Lower Hydrogen Consumption and Reduced Octane Number Loss: In the coupling process, most olefins do not enter a hydrogenation environment, leading to significantly reduced hydrogen consumption and minimized octane number loss.

- Reduced Cracking Reactions and Processing Losses: Since the majority of olefins do not enter the high-temperature catalytic environment, the coupling process experiences fewer cracking reactions, thereby reducing oil processing losses.

- Mitigated Fouling and Coking in Heaters: The coupling process ensures that most diolefins are excluded from the S-Zorb feedstock. This significantly alleviates fouling and coking in heaters, extending the operational cycle between maintenance shutdowns.

- Flexibility to Address Benzene Content Issues: The coupling process provides the flexibility to handle cases where the benzene content in RCT gasoline exceeds regulatory standards.

Extractive Hydrogenation Desulfurization Coupled with S-Zorb: A Summary of Advantages

This section outlines the benefits of combining the extractive hydrogenation desulfurization (EHDSO) technology with Sinopec's S-Zorb adsorption desulfurization process:

- Simplified Capacity Expansion and Cost Reduction

S-Zorb units face challenges when expanding capacity. By diverting a portion of the S-Zorb feedstock for desulfurization using the extractive method (e.g., targeting the lighter fractions), the original S-Zorb unit requires minimal modification. This significantly reduces the investment cost and simplifies implementation. - Reduced Hydrogen Consumption and Octane Preservation

The lighter fractions of catalytic gasoline, rich in olefins, are treated using extractive desulfurization. This prevents these olefins from entering the hydrogenation environment, leading to lower hydrogen consumption and less octane number loss. - Lower Oil Processing Losses

S-Zorb operates at a high temperature (around 400°C), which can lead to olefin cracking and oil processing losses. By coupling with EHDSO, fewer olefins are exposed to the high-temperature catalytic environment, reducing cracking reactions and oil processing losses. - Alleviated Fouling and Coking Issues

Full-range feedstocks in S-Zorb often contain diolefins, which can cause fouling and coking during pre-heating and vaporization. With EHDSO handling the light fractions, diolefins bypass the high-temperature vaporization process, significantly mitigating these issues. - Enhanced Benzene Removal

In the context of RCT (Residual Catalytic Technology) processes that produce high-benzene gasoline, the coupling approach provides an effective solution for benzene removal. This simplifies the overall processing flow and ensures compliance with regulatory standards.

Conclusion

The EHDSO-S-Zorb coupling technology not only addresses limitations in feedstock adaptability and operational flexibility but also optimizes costs, reduces processing losses, and preserves fuel quality. It is a practical and cost-effective solution for refiners facing challenges in desulfurization, octane preservation, and compliance with benzene limits.

Liquefied Petroleum Gas (LPG) Deep Desulfurization and Cleaning Technology – Advanced Desulfurization

Advantages and Characteristics of LPG Deep Desulfurization and Cleaning Technology:

- Recognized Technological Excellence:

This technology has won the China Petroleum and Chemical Industry Federation (CPCIF) Technology Invention Award (Second Prize) and has been identified by the Chemical Industry Environmental Protection Association as a key technology supporting environmental protection and clean production. It has also been evaluated by the Petrochemical Federation as achieving an internationally advanced level. - Addressing High Total Sulfur Issues:

The technology effectively resolves the challenge of high total sulfur levels after traditional mercaptan removal processes. It ensures:- Catalytic LPG with total sulfur levels below 5 ppm (industrial applications have achieved results as low as 1 ppm).

- Coker LPG with total sulfur levels below 50 ppm.

- Proven Industrial Performance:

The technology has been adopted in over 100 installations, with dozens of fiber membrane mercaptan removal units successfully upgraded. Its ability to achieve ultra-low sulfur levels after treatment is one of its primary advantages.

This advanced desulfurization technology is a game-changer for LPG processing, providing reliable solutions for meeting stringent sulfur specifications in both catalytic and coker-derived LPG streams.

Liquefied Petroleum Gas (LPG) Deep Desulfurization and Cleaning Technology: An Integrated Solution

The LPG deep desulfurization and cleaning technology consists of three distinct yet interconnected components:

- Deep Desulfurization

- Zero Tail Gas Emissions

- Zero Alkaline Waste Discharge

These components can be implemented independently or as an integrated solution.

Recognition and Validation

- Awarded the Technology Invention Second Prize by the China Petroleum and Chemical Industry Federation (CPCIF).

- Recognized as a key technology for environmental protection and clean production by the Petrochemical Federation and the Chemical Industry Environmental Protection Association.

- Officially appraised as achieving an international advanced level, with the "zero alkaline waste discharge" and "zero tail gas emissions" components regarded as world-leading technologies.

Key Features and Strengths

- Addressing High Sulfur Levels Post-Mercaptan Removal:

- For catalytic LPG, the technology guarantees sulfur levels below 5 mg/m³ after treatment, with the best industrial results achieving levels below 1 mg/m³.

- For coker LPG, it ensures sulfur levels below 50 mg/m³, with real-world examples like Tianjin Petrochemical’s coker LPG achieving consistent levels below 30 mg/m³.

- Industrial Performance:

- This technology has been implemented in over 100 installations, with many domestic fiber membrane units upgraded using this approach.

- Deep Desulfurization Advantage:

- The primary advantage lies in achieving ultra-low sulfur levels post-treatment, making it a standout solution for LPG desulfurization needs.

This combination of technical innovation and proven industrial results makes the LPG deep desulfurization and cleaning technology a benchmark for modern LPG processing.

Liquefied Gas Deep Desulfurization and Clean Technology – Zero Tail Gas Emission

Advantages and Features: The tail gas from the desulfurization alcohol regeneration process contains hazardous and polluting compounds, including hydrocarbons, oxygen, sulfur species, and alkalis. Due to its volatile composition, this tail gas presents significant safety hazards and environmental risks during downstream processing. This technology represents the first application of intrinsic safety design in the desulfurization alcohol regeneration cycle. The zero tail gas emission unit incorporates advanced techniques such as on-demand oxygen generation and tail gas recirculation, ensuring intrinsic safety while facilitating the resource recovery and recycling of hazardous tail gas emissions. These measures lead to a dual enhancement in both operational safety and environmental sustainability, offering a cleaner and safer alternative to traditional desulfurization processes.

The clean technology primarily achieves zero tail gas emissions. The desulfurization alkylation liquor’s alkali solution was previously regenerated via air oxidation, which resulted in the production of tail gas. This tail gas contains hydrocarbons, oxygen, sulfur compounds, alkalis, and water. Historically, such tail gas was either directed to sulfur recovery incinerators or boilers. Under normal operational conditions, this posed no significant issues, but due to the volatile composition, uncontrolled flow rates, equipment malfunctions, instrumentation errors, or human mistakes, the tail gas could enter an explosive zone. Many companies have experienced flash explosion incidents as a result. In response, Sinopec has issued directives mandating that tail gas from the desulfurization alcohol regeneration process must be treated as a safety hazard.

Zero tail gas emissions essentially means the complete recycling of tail gas. The most critical challenge in tail gas treatment lies in ensuring safety, and the primary obstacle in tail gas recycling continues to be safety-related. The standout feature of our technology is its ability to address the safety concerns associated with tail gas recycling. Previous technologies did not account for the intrinsic safety of the desulfurization alcohol regeneration process or for how to regulate oxidative regeneration to keep it outside the explosive limit. Hebei Refining Technologies (Hebei Jingzhi) pioneered research into the intrinsic safety of the desulfurization alcohol regeneration process, identifying the explosive hazard zone of the tail gas and proposing safe operating conditions outside the explosive range. The concept of intrinsic safety design for desulfurization alcohol regeneration was first introduced by Hebei Jingzhi.

Zero tail gas emissions require continuous replenishment of the oxygen that is consumed during the process. The zero-emission unit is equipped with an oxygen-enriched air separation system, which generates the necessary oxygen to replenish what is consumed by the tail gas. Importantly, no oxygen storage equipment is involved in the process, ensuring that oxygen is used without being stored, thus mitigating safety risks related to oxygen accumulation.

Tail gas contains hydrocarbons and oxygen, which are essential for the regeneration process. The most effective way to prevent tail gas from entering an explosive environment is through the manual control of hydrocarbon content within the regeneration system, maintaining the hydrocarbon concentration above the explosive limit. To ensure safety, the hydrocarbon content in the tail gas must remain above 15% by volume, typically operating at around 25% by volume. This ensures the tail gas is kept outside the explosive range. By recycling tail gas, valuable hydrocarbons are reused, significantly reducing waste emissions and contributing to resource recovery. The economic benefits are substantial. Preliminary calculations suggest that at a hydrocarbon content of 25%, every cubic meter of tail gas contains at least 1 kilogram of gasoline. If the tail gas is discharged, that 1 kilogram of gasoline would be lost as waste. Hence, zero tail gas emissions deliver not only environmental benefits but also significant economic returns. We have already achieved considerable success, with some of our earliest projects having been operational for over five to six years.

Liquefied Gas Deep Desulfurization Clean Technology – Alkali Residue Zero Emission

Advantages and Features: Alkali residue, containing significant amounts of biotoxic substances, organic amines, organic acid salts, emulsified oils, and excess inorganic strong alkalis, is widely recognized as one of the most difficult hazardous wastes to treat in the refining industry. This technology employs amine optimization and water washing for amine removal as source control measures, reducing the H2S concentration in the raw liquefied gas from 20 ppm to below 5 ppm and amine content from 200 ppm to 2 ppm, effectively controlling 90% of pollutant carryover. Subsequently, solvent upgrading is implemented to enhance the solvent’s pollutant absorption capacity, combined with online purification to achieve zero or near-zero alkali residue emissions.

Alkali Residue Zero Emission

As is well known, the desulfurization alcohol process requires the use of alkali, and after a certain period of operation, alkali residue must be disposed of, which is characteristic of traditional desulfurization alcohol technology. We now introduce the concept of alkali residue zero emission. The alkali residue from desulfurization alcohol primarily contains biotoxic substances such as sulfur thiol, hydrogen sulfide, along with alkalis and organic amines. In the desulfurization alcohol process, the amine stripping step can result in organic amines being carried into the desulfurization alcohol system, where they are oxidized to form organic acids. These organic acids act as emulsifiers, further intensifying the emulsified oil in the alkali solution. As a result, the Chemical Oxygen Demand (COD) of desulfurization alcohol alkali residue is unusually high, typically exceeding 300,000, making it extremely difficult to treat.

The key concept of alkali residue zero emission is source control of pollutants. The harmful substances primarily originate from the amine stripping process. Issues arise when the amine stripping is ineffective or when excess amine is carried over. Therefore, the first measure for alkali residue zero emission is the optimization of amine stripping. During the liquefied gas amine stripping, the goal is to reduce hydrogen sulfide and carbon dioxide to low levels, necessitating modifications to the traditional amine stripping unit. Following the amine stripping, an additional water wash step is implemented to recover the amine. The amine concentration in the liquefied gas is generally around 200-300 ppm, and we aim to reduce this to 2 ppm using water washing. A key technical challenge here is to achieve this high level of purification using a minimal amount of water. Since amine recovery is essential, large amounts of water cannot be used. The amine concentration at the bottom of the tower should be around 5%, which allows the amine to be reintroduced into the rich amine solution, thus maintaining the balance of the amine system. If excessive water is used, the recovered solution will turn into amine-containing wastewater, which would still require treatment, failing to achieve clean technology. The benefits of amine recovery are significant. For every ton of liquefied gas, 2 yuan of amine solution can be recovered. If the amine is degraded in wastewater treatment, it costs at least another 2 yuan for treatment, saving a total of 4 yuan in processing fees. With an annual liquefied gas processing volume of 500,000 tons, this method can save 2 million yuan annually in amine recovery.

Another measure for alkali residue zero emission is solvent upgrading. Sodium hydroxide is prone to salting-out and has limited ability to resist contamination. We have upgraded the solvent to not only improve desulfurization activity but also enhance its pollutant absorption capacity. When sodium hydroxide was used in the past, the carbonate content exceeding 2-3% would prevent sulfur thiols from dissolving. The new solvent, with a total salt content of 30%, maintains stable desulfurization alcohol performance, which is its main advantage.

The third measure for alkali residue zero emission is online purification. Over time, or if earlier operational control is suboptimal, the solvent may accumulate excessive salt content. In such cases, an online purification process is required. We provide on-site online service to thoroughly purify systems that have been in use for 1-2 years, ensuring that the system remains stable for another 1-2 years after purification, achieving alkali residue zero emission.

Refinery Gas Amine Stripping System Optimization and Energy-saving Emission Reduction Technology

Comprehensive Solution for Amine Stripping System Efficiency, Energy Saving, and Emission Reduction

As the amine solution systems grow in scale and the complexity of contamination factors increases, many units operate in a low-efficiency and unstable state. This technology addresses these challenges through a combination of pollutant classification pretreatment, the use of high-sulfur-load solvents, and efficient online purification techniques, ensuring that the amine solution remains in optimal condition throughout its lifecycle.

By optimizing the amine circulation and improving system stability, this solution achieves over 20% energy savings in the amine stripping process. It also eliminates the traditional challenges of generating large amounts of difficult-to-treat wastewater during the purification phase. Through these innovations, the technology significantly enhances operational efficiency, reduces environmental impact, and supports sustainable refining practices, resulting in both energy conservation and emission reduction.

Key Measures for Amine Stripping Optimization:

- Pollutant Classification and Pretreatment: Implement classification or pretreatment of sulfur-containing contaminants in the desulfurization medium, optimizing the process equipment to manage sulfur load and purification efficiency.

- Pre-Amine Stripping Measures: Address issues of feedstock sulfur load exceeding design specifications by implementing pre-treatment strategies, enabling flexible capacity expansion of the system to accommodate variable sulfur content.

- Mass Transfer Equipment Optimization: Enhance the efficiency of H2S removal, selectivity, and the treatment capacity of existing equipment by optimizing the mass transfer equipment used in the amine stripping process.

- Enhanced Desulfurization Agents: Develop and apply functionalized desulfurizing agents to increase the sulfur load capacity and regeneration efficiency, which in turn reduces the circulation volume and energy consumption by more than 20%.

- Pre-Removal of Key Impurities: Focus on the removal of problematic contaminants such as chlorides (Cl), oxygen (O), heavy hydrocarbons, and carbon soot to prevent contamination and ensure the system operates at peak efficiency without the need for extensive post-treatment.

- Process and Solvent Simulation: Use process simulation software and solvent testing to develop customized formulations that address specific operational challenges and optimize system performance.

- Comprehensive Monitoring Service: Offer comprehensive monitoring of the amine solution system’s operational status to maintain optimal conditions and facilitate early detection of potential issues.

- Efficient Purification Measures: Implement high-efficiency purification methods that address multifactorial contamination while eliminating the generation of large amounts of difficult-to-treat wastewater, thereby ensuring environmental sustainability and operational efficiency.

By adhering to a prevention-first, comprehensive management approach, these measures contribute to improved system stability, energy efficiency, and emission reduction throughout the desulfurization process.

Amine Stripping System Optimization: A Comprehensive Solution for Efficiency, Energy Saving, and Emission Reduction

The amine stripping system is a critical area of research for us, with a focus on enhancing efficiency, energy conservation, and emission reduction. With the trend toward scale-up and integration in refining processes, most of the sulfur compounds in refinery products are converted into hydrogen sulfide (H2S) through hydrotreating and then removed by the amine solution. This shift results in two major challenges: on the one hand, the amine system is becoming increasingly large, and on the other hand, the complexity of contaminants in the amine solution is increasing. Many existing systems operate inefficiently and unstably, with foam formation being a major issue.

Our approach to amine stripping optimization follows the principles of clean technology, energy efficiency, and emission reduction. The first step is to classify contaminants and implement pre-treatment for the most impactful pollutants, preventing them from entering the amine system and creating a "pollute first, treat later" scenario. The second step is to utilize high-sulfur composite solvents that outperform conventional solvents, optimizing the formulation to improve the amine solution’s overall performance, which allows for amine concentrations up to 40% or higher. The third key measure is the implementation of efficient, energy-saving online purification techniques. Depending on the specific needs of each refinery, various adaptive measures are available, but these three key steps ensure that the amine solution always remains in optimal condition.

The overall goal of amine stripping optimization is to reduce energy consumption by more than 20%, while eliminating the environmental and operational challenges posed by traditional purification methods, such as the generation of difficult-to-treat wastewater.

In addition to these three key measures, we would like to highlight the pre-amine stripping solution, which is an effective approach for addressing the overload in amine stripping towers. When a desulfurization tower is overloaded, increasing the tower diameter and height is often necessary, but this can strain the existing tower foundation, which may not meet the new requirements. Since tower foundation construction takes considerable time, it’s often impractical to extend maintenance cycles. In such cases, we propose pre-amine stripping: adding a pre-stripping facility before the desulfurization tower. We have successfully implemented this solution in two projects, which addressed up to 50% overload and mitigated the challenge of shortened maintenance times.

Furthermore, we have made improvements to the mass transfer equipment used in desulfurization, especially with regard to selectivity and liquid-liquid mass transfer. For example, many enterprises struggle with poor desulfurization performance due to ineffective liquid-liquid mass transfer. Our patented mass transfer equipment solves this issue and enhances desulfurization efficiency.

Additionally, we’ve optimized process flows and equipment structures, including improvements in flash tanks for oil removal, homogenization, and amine solution tanks for oxygen isolation. We strongly recommend that, during the construction or expansion of new facilities, refineries adopt our process packages that incorporate the latest concepts and designs in amine stripping optimization. This comprehensive approach guarantees better operational stability, energy efficiency, and sustainability.

Amine Stripping Optimization – Functionalized Desulfurization Agents

Advantages and Features: The amine stripping system accounts for approximately 10% of the total energy consumption in refining, making it a critical area for energy-saving initiatives. By adopting functionalized desulfurization agents, we enhance the amine concentration in the solvent, which enables the system to handle high sulfur loads more efficiently. This innovation allows for a reduction in the amine circulation volume, directly contributing to lower energy consumption and improving overall process efficiency.

| 客户名称 | 应用胺液系统 | 溶剂再生规模 | 应用目的 | 时间 |

| 中石化-北海炼化 | 非临氢及焦化脱硫系统 | 160t/h | 强化脱硫 | 2012年 |

| 中石化-天津石化 | 非临氢及焦化脱硫系统 | 310t/h | 强化脱硫 | 2012年 |

| 中石化-荆门石化 | 非临氢及焦化脱硫系统 | 300t/h | 强化脱硫 | 2012年 |

| 中石化-燕山石化 | 硫磺尾气脱硫系统 | 125t/h | 强化脱硫 | 2014年 |

| 中石油-大港石化 | 非临氢及焦化脱硫系统 | 200t/h | 强化脱硫 | 2012年 |

| 北方兵器-华锦石化 | 非临氢及焦化脱硫系统 | 300t/h | 节能降耗 | 2014年 |

| 中石化-青岛炼化 | 临氢、非临氢及焦化脱硫系统 | 450t/h;350t/h | 强化脱硫 | 2014年 |

| 中石化-青岛石化 | 非临氢脱硫系统 | 60t/h | 节能降耗 | 2014年 |

| 中石油-吉林石化 | 非临氢及焦化脱硫系统 | 130t/h | 节能降耗 | 2014年 |

| 中石油-玉门石化 | 非临氢及焦化脱硫系统 | 60t/h | 强化脱硫 | 2014年 |

| 中石油-锦西石化 | 非临氢及焦化脱硫系统 | 120t/h | 强化脱硫 | 2015年 |

| 中石油-呼和浩特 | 临氢、非临氢及硫磺尾气脱硫系统 | 90t/h | 强化脱硫及再生 | 2016年 |

| 中石化-武汉石化 | 临氢、非临氢及焦化脱硫系统 | 90t/h;120t/h | 强化脱硫及节能 | 2017年 |

| 中海油-东方石化 | 非临氢脱硫系统 | 200t/h | 强化脱硫 | 2018年 |

| 中石化-镇海炼化 | 非临氢脱硫系统 | 100t/h | 强化脱硫 | 2019年 |

| 中化泉州石化 | 非临氢脱硫系统 | 500t/h | 节能降耗 | 2020年 |

| 中海油大榭石化 | 非临氢及临氢脱硫系统 | 120t/h | 强化脱硫及再生 | 2021年 |

| 中海油惠州炼化 | 临氢、非临氢及焦化脱硫系统 | 200t/h | 节能降耗 | 2022年 |

| 中石化洛阳石化 | 非临氢及临氢及硫磺尾气脱硫系统 | 300t/h;300t/h;300t/h | 节能降耗 | 2022年 |

| 中石化长岭石化 | 临氢及非临氢系统 | 90t/h;110t/h | 节能降耗 | 2022年 |

| 中石化茂名石化 | 非临氢系统 | 550t/h | 节能降耗 | 2023年 |

The use of functionalized agents ensures the system can operate under high sulfur loads, while maintaining optimal amine performance. This technology is essential for refineries aiming to reduce their energy consumption, cut operational costs, and enhance the environmental sustainability of their processes.

This is the application performance of our high-capacity desulfurization agents at Sinopec. Initially, the technology was primarily used to address situations where desulfurization did not meet the required standards. By adding additives, we were able to enhance the desulfurization capacity.

More recently, however, it has been increasingly used for energy-saving purposes. In these cases, the desulfurization process is already compliant, but there is a need to reduce energy consumption. By incorporating our high-capacity desulfurization agent, the amine circulation volume is reduced, leading to lower energy usage and improved overall system efficiency. This shift reflects the growing trend of leveraging advanced technology not just to meet compliance standards, but also to optimize energy efficiency and enhance sustainability in refining operations.

Amine Stripping Optimization – Extractive Distillation Online Purification Technology

Advantages and Features: The amine solution is subject to contamination by factors such as anion thermal stable salts, colloidal heavy hydrocarbons, and micro-solids, all of which act as foaming agents. Conventional ion exchange and electrodialysis methods have poor anti-contamination capabilities, making them unsuitable for long-term stable operation. Moreover, the treatment of amine-contaminated wastewater generated by these systems is economically unfeasible.

Our extractive distillation online purification technology addresses these issues by offering a stronger anti-contamination capability, effectively solving the problem of multifactorial contamination. The technology ensures thorough purification, with low energy consumption, minimal amine loss, and reduced waste disposal. This solution significantly improves the operational stability and efficiency of amine stripping systems while minimizing environmental impact, making it a cost-effective and sustainable choice for refineries.

| 项目 | 离子交换树脂净化 | 电渗析净化 | 在线萃取蒸馏净化 |

| 技术原理 | 通过离子交换树脂实现阴离子的脱除 | 利用选择性透过膜实现阴阳离子的脱除 | 通过萃取蒸馏实现全因素污染物的脱除 |

| 解决的问题 | 酸式热稳盐 | 酸式+碱式热稳盐 | 热稳盐、发泡、冲塔、堵塞等全污染因素 |

| 进料要求 | 需要脱油固预处理 | 需要严格脱油脱固预处理 | 不需要 |

| 排废形式 | 含胺含碱废液 | 含胺废液 | 含胺废固 |

| 排废量/胺液藏量 | 100~150% | 20~50% | 1~5% |

| 排废胺含量 | 1~2% | 3~5% | 5~10% |

|

脱除1t热稳盐 能耗(kgEo/t) |

17357.63 | 2486.09 | 528.56 |

| 优势与劣势 |

适合污染因素单一、污染程度不高的环境。 含胺废水量大,回系统重复蒸馏能耗大; 含胺废碱液处理难度大;向系统夹带钠离子。 |

与离子交换比较:产生的废水量少,但含胺更高,处理更困难;草酸根、硫代硫酸根较高时容易堵膜;需要更精密的脱油脱固预处理;可以脱钠离子。 | 抗污染能力强,同时解决全因素污染问题,适合污染因素复杂、较庞大体系的在线净化。净化彻底、能耗低、排废及胺损最少。 |

Amine Stripping System Optimization – Extractive Distillation Online Purification Technology

Advantages and Features: One of the most common and challenging issues in amine stripping systems is foaming. As amine liquid systems grow larger and more complex, the contamination factors accumulate, leading to more severe foaming problems. These contaminants include thermal-stable anionic salts, colloids, heavy hydrocarbons, and micro-solids, which exacerbate foaming. While ion exchange and electrodialysis are commonly used purification methods, they share the common problem of poor anti-contamination capabilities and limited effectiveness in controlling foaming. Additionally, these methods often generate significant amounts of amine-containing wastewater, which cannot always be processed by wastewater treatment plants and require distillation for further purification. This scenario highlights the current challenges and inefficiencies in amine liquid purification.

To address these issues, we developed the extractive distillation online purification technology, which overcomes the limitations of traditional purification methods. Here’s a breakdown of the challenges with conventional methods:

- Ion exchange: The process involves passing amine liquid through resin, where anionic contaminants are adsorbed, particularly targeting thermal-stable salts. After resin saturation, the amine is washed out with water, followed by alkaline treatment to remove anions. However, completely washing out the alkali is challenging, leading to the introduction of sodium ions into the amine system, and the process generates large amounts of wastewater and alkaline wastewater. This results in high energy consumption and operational inefficiency, with each ton of thermal-stable salt processing costing significant energy, water evaporation, and wastewater disposal.

- Electrodialysis: Although electrodialysis is somewhat better than ion exchange due to reduced wastewater generation and no sodium ion contamination, it still faces serious limitations. The membranes in electrodialysis are highly susceptible to fouling if the amine liquid is heavily contaminated. Furthermore, the wastewater produced by electrodialysis has a high amine concentration, which many wastewater treatment plants cannot handle, requiring additional distillation.

In response to these shortcomings, our extractive distillation technology works by introducing an agent that transforms thermal-stable salts and foaming agents into high-boiling components, which can then be separated via distillation. This technology ensures effective purification while also minimizing waste and energy consumption.

Key benefits of extractive distillation technology:

- Energy Efficiency: The system utilizes two distillation columns, where the steam used in the first column is fully recovered and returned as vapor to the regeneration tower, significantly reducing energy loss. Given that amine liquids typically contain around 40% amine and 60% water, the heat capacity and latent heat of water are higher than that of amine, meaning that up to 70% of the purification energy is recaptured and reused, drastically reducing energy consumption.

- Waste Minimization: After distillation, the water is returned to the regeneration tower, and waste is removed as solid residue. The amount of solid residue is minimal, with continuous operation producing less than 1% of waste solids. For example, in a year of continuous operation at Dazhi, the solid residue yield was just 0.46%. The amine liquid loss was reduced from over 400 tons annually to about 50-60 tons, achieving significant reduction in waste discharge.

- Adaptability: This technology has strong adaptability and doesn’t require specific pre-treatment. It can effectively purify amine liquids with various contamination factors, making it an ideal solution for large-scale amine systems that experience severe foaming and contamination. It offers a high-efficiency, energy-saving, and low-emission solution without the need for additional wastewater treatment.

This online extractive distillation purification technology has been patented and is highly effective for large amine systems, especially when amine liquid concentration needs to be increased during amine stripping optimization. Without this technology, increased foaming could lead to larger operational losses.

Keyword:

Next article

Related News

Public Notice on the Greenhouse Gas Emission Verification Report

Public Notice on the Greenhouse Gas Emissions Verification Report

2023-03-06

On November 16, 2022, the Euro IV gasoline upgrading project at the Hengyuan Refinery in Malaysia was successfully started up, producing qualified products. This project uses our company's gasoline extraction and hydro-desulfurization combined desulfurization technology (referred to as "EHDS"), which won the second prize of the National Technological Invention Award. Our company provides a complete process package for pre-hydrogenation, extraction desulfurization, and heavy gasoline hydrogenation, with Global Company as the general contractor. At the request of the owner and Global general contractor, an experienced team of technical experts was sent to the site in July 2022. In the face of the risk of the epidemic, they actively participated in the cooperation of various stages of the device "three checks and four determinations", sealing test, water linkage transportation, and commissioning, and carefully carried out the work.

2022-12-05

On July 7, Hebei Jingzhi Technology Co., Ltd. and China Tianchen Engineering Co., Ltd. signed a strategic cooperation framework agreement in Tianjin. Mr. Hao Tianzhen, Chairman of Hebei Jingzhi Technology Co., Ltd., and Mr. Zhou Mingsheng, Managing Director of China Tianchen Engineering Co., Ltd., signed on behalf of their respective companies. Prior to the ceremony, both parties conducted friendly exchanges on their respective business areas and future cooperation directions, and conducted in-depth discussions on strategic cooperation in areas such as engineering services and technological research and development. Chairman Hao Tianzhen stated that Hebei Jingzhi will cooperate with Tianchen in the future on a full range of advanced desulfurization technologies, gasoline refining technologies, and liquefied gas deep desulfurization technologies.

2022-07-14

Hebei Jingzhi Technology Co., Ltd. Announcement on Sewage Discharge Information

I. Basic Information (1) Company Name: Hebei Jingzhi Technology Co., Ltd.; Address: East Zone, Cangzhou Port Economic and Technological Development Zone, east of Tongliu Road, south of Huagong No. 1 Road; Legal Representative: Hao Tianzhen (2) Main Pollutant Names: Wastewater: Ammonia nitrogen, pH, suspended solids, COD, total nitrogen, petroleum, toluene, xylene, five-day biochemical oxygen demand; Waste gas: Methanol, non-methane total hydrocarbons, toluene + xylene, particulate matter, ozone concentration; Discharge method: Wastewater is discharged to the Gangcheng sewage treatment plant after treatment; Waste gas is discharged into the atmosphere through the chimney after treatment; Discharge concentration

2022-04-20