Zero Emission Technology for LPG Mercaptan Removal Off-Gas

Release time:

2025-05-30

As global environmental standards tighten and operational efficiency becomes increasingly vital, petrochemical and natural gas producers are seeking sustainable and cost-effective solutions to manage process emissions. This whitepaper introduces Hebei Refining Technologies’ advanced zero-emission technology for LPG mercaptan removal off-gas, a field-proven solution that simultaneously eliminates emissions, improves caustic regeneration efficiency, and reduces operational costs.

Whitepaper

Zero Emission Technology for LPG Mercaptan Removal Off-Gas

Published by: Hebei Refining Technologies (HRT)

Date: May 29, 2025

Abstract

As global environmental standards tighten and operational efficiency becomes increasingly vital, petrochemical and natural gas producers are seeking sustainable and cost-effective solutions to manage process emissions. This whitepaper introduces Hebei Refining Technologies’ advanced zero-emission technology for LPG mercaptan removal off-gas, a field-proven solution that simultaneously eliminates emissions, improves caustic regeneration efficiency, and reduces operational costs.

1. Industry Challenge: Emissions from Mercaptan Removal

In traditional LPG mercaptan removal processes, off-gas streams generated during caustic solvent regeneration are typically routed to acid gas incinerators or flare systems. In the BLK9 Project in Iraq, this approach led to several operational issues:

- The acid gas incinerator was overloaded due to hydrocarbon entrainment.

- Temporary diversion of off-gas to flare systems resulted in environmental and efficiency concerns.

- High oxygen content (~12%) in the off-gas required excessive natural gas injection to remain combustible, increasing costs and complicating system design.

Maintaining oxygen concentrations below 2% for safe incineration or flaring often required natural gas flow rates five times higher than the oxidation air, far exceeding system design limits and resulting in unsustainable operations.

Furthermore, limiting hydrocarbon content to control oxygen levels negatively impacted the caustic regeneration process, requiring frequent replacement of caustic solution, increased waste discharge, and reduced product quality.

2. HRT's Solution: Closed-Loop Zero Emission System

HRT proposes a closed-loop off-gas recycling system that eliminates the need for flaring or incineration while maintaining the integrity of the regeneration process.

Core Benefits:

- Eliminates emissions entirely from mercaptan removal off-gas.

- Minimizes oxygen input using high-purity oxygen injection.

- Improves solvent regeneration efficiency and sulfur recovery.

- Reduces OPEX by cutting hydrocarbon and caustic losses.

3. Technical Overview

3.1 Source and Composition of Off-Gas

Off-gas originates from oxidation air used in caustic regeneration. Although the air is injected to oxidize sodium mercaptide, only ~30% is utilized; the rest is vented with the off-gas, which also contains:

- Residual oxygen (12–15%)

- Hydrocarbons

- Caustic carryover

- Sulfur compounds

- Water vapor

3.2 Core Technologies and Mitigation Measures

- Off-Gas Compressor Skid: Pressurizes the off-gas for safe and effective recycling back into the regeneration tower.

- Oxygen Enrichment Skid: Replaces ambient air with a controlled mix of oxygen and nitrogen to precisely match the process demand.

- Online O₂-Hydrocarbon Analyzer: Monitors and adjusts the oxygen/hydrocarbon ratio for safe combustion and regeneration conditions.

- High-Efficiency Oxygen Mixer: Ensures homogeneous mixing of off-gas and oxygen, eliminating local O₂ hotspots and maintaining safety.

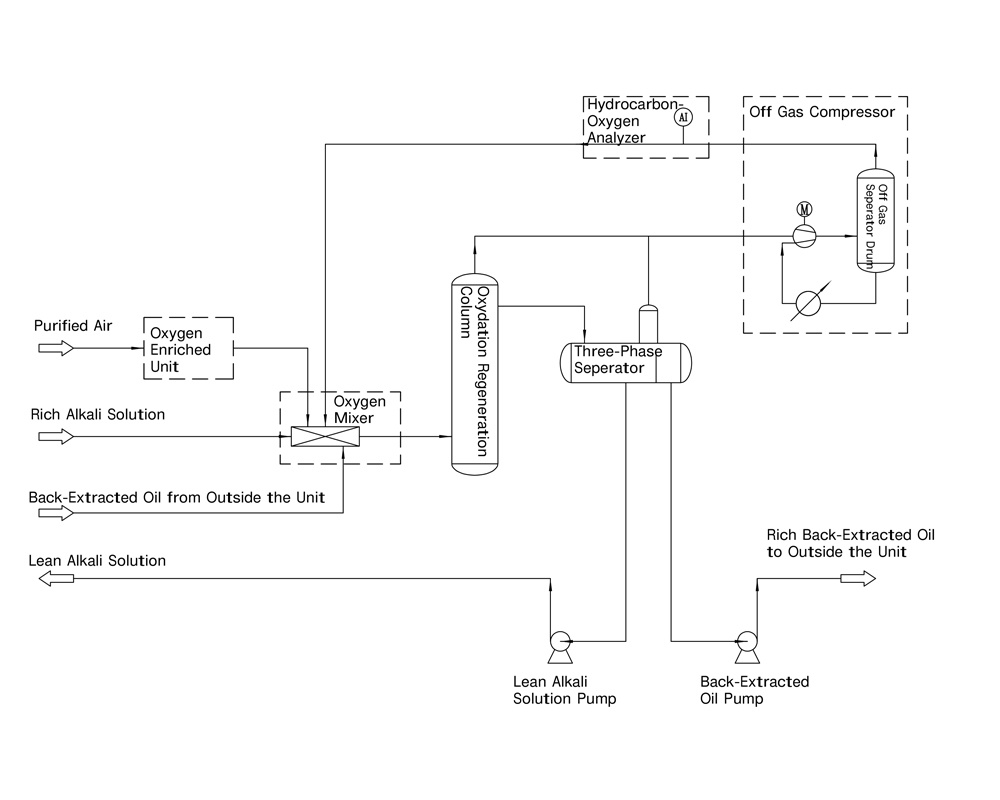

4. Process Flow Description

The system integrates with the caustic regeneration section of LPG treatment. Key process steps include:

1. Mixing: Rich solvent, recycled off-gas, oxygen, and extractive oil are blended in an oxygen mixer.

2. Regeneration: In the oxidation tower, sodium mercaptide is catalytically oxidized to disulfide, which dissolves in extractive oil.

3. Separation & Recirculation: The extractive oil is separated, partially recycled, and partially discharged as disulfide-rich oil.

4. Compression & Reuse: Off-gas is compressed, dehydrated, and recirculated—monitored and balanced by the oxygen analyzer system.

Below is the process flow diagram for the zero-emission off-gas recycling system:

5. Typical Equipment Package

| No. | Equipment | Quantity | Description |

| 1 | Off-Gas Compression Skid (incl. cooler) | 1 set | Circulates and pressurizes off-gas |

| 2 | Oxygen Enrichment Skid | 1 set | Generates high-purity oxygen blend |

| 3 | Oxygen Mixer | 2 sets | Ensures safe and even gas distribution |

| 4 | Online Oxygen-Hydrocarbon Analyzer | 2 units | Real-time process safety and optimization |

6. Economic and Environmental Impact

- ✅ Eliminates environmental emissions from mercaptan off-gas

- ✅ Saves over 1.5 million RMB/year (~$210,000) in hydrocarbon losses

- ✅ Avoids cost and risk of overloading flare or incinerator systems

- ✅ Over 20 successful installations across China prove operational safety and reliability

7. Conclusion

HRT’s zero-emission off-gas technology addresses a long-standing bottleneck in sulfur removal and gas treatment systems. By replacing flaring with a closed-loop oxygen-based process, it empowers operators to meet regulatory, economic, and operational demands simultaneously.

Whether you’re upgrading an existing LPG unit or designing a greenfield project, HRT offers scalable, field-tested solutions that deliver results.

Contact Us

Hebei Refining Technologies Co., Ltd.

🌐 www.refinehorizon.com

📧 info@hbreftech.com

📞 +86 317 797 2698

Keyword:

Previous

Related News

Public Notice on the Greenhouse Gas Emission Verification Report

Public Notice on the Greenhouse Gas Emissions Verification Report

2023-03-06

On November 16, 2022, the Euro IV gasoline upgrading project at the Hengyuan Refinery in Malaysia was successfully started up, producing qualified products. This project uses our company's gasoline extraction and hydro-desulfurization combined desulfurization technology (referred to as "EHDS"), which won the second prize of the National Technological Invention Award. Our company provides a complete process package for pre-hydrogenation, extraction desulfurization, and heavy gasoline hydrogenation, with Global Company as the general contractor. At the request of the owner and Global general contractor, an experienced team of technical experts was sent to the site in July 2022. In the face of the risk of the epidemic, they actively participated in the cooperation of various stages of the device "three checks and four determinations", sealing test, water linkage transportation, and commissioning, and carefully carried out the work.

2022-12-05

On July 7, Hebei Jingzhi Technology Co., Ltd. and China Tianchen Engineering Co., Ltd. signed a strategic cooperation framework agreement in Tianjin. Mr. Hao Tianzhen, Chairman of Hebei Jingzhi Technology Co., Ltd., and Mr. Zhou Mingsheng, Managing Director of China Tianchen Engineering Co., Ltd., signed on behalf of their respective companies. Prior to the ceremony, both parties conducted friendly exchanges on their respective business areas and future cooperation directions, and conducted in-depth discussions on strategic cooperation in areas such as engineering services and technological research and development. Chairman Hao Tianzhen stated that Hebei Jingzhi will cooperate with Tianchen in the future on a full range of advanced desulfurization technologies, gasoline refining technologies, and liquefied gas deep desulfurization technologies.

2022-07-14

Hebei Jingzhi Technology Co., Ltd. Announcement on Sewage Discharge Information

I. Basic Information (1) Company Name: Hebei Jingzhi Technology Co., Ltd.; Address: East Zone, Cangzhou Port Economic and Technological Development Zone, east of Tongliu Road, south of Huagong No. 1 Road; Legal Representative: Hao Tianzhen (2) Main Pollutant Names: Wastewater: Ammonia nitrogen, pH, suspended solids, COD, total nitrogen, petroleum, toluene, xylene, five-day biochemical oxygen demand; Waste gas: Methanol, non-methane total hydrocarbons, toluene + xylene, particulate matter, ozone concentration; Discharge method: Wastewater is discharged to the Gangcheng sewage treatment plant after treatment; Waste gas is discharged into the atmosphere through the chimney after treatment; Discharge concentration

2022-04-20